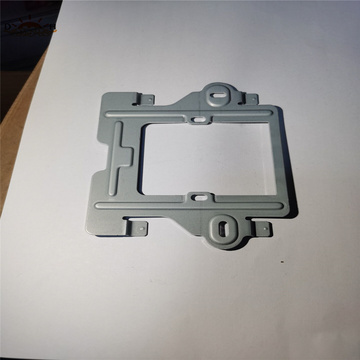

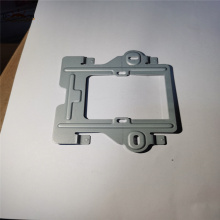

OEM/ODM Metal Stamping Sheet Metal Fabrication Auto Parts

| Payment Type: | L/C,T/T,Western Union |

|---|---|

| Terms of Trade: | FOB,CFR,CIF,EXW |

| Min. Order: | 1 Set/Sets |

| Delivery Time: | 25-30 Days |

| Packaging: | Standard exported Wooden box packed, Fumigation process(upon required) |

|---|---|

| Brand: | DoHform |

| Transportation: | Ocean,Land,Air |

| Place of Origin: | Kunshan,China |

| Port: | Shanghai,Ningbo,China |

Click on the follow link to find out more information: https://www.dhform.com/metal-parts-for-car-interior/

Company Info

- Company Name: DongHui Mold Machinery Co.Ltd

- Representative: Ding Huan Chen

- Product/Service: Injection Molds , Plastic Moulds , Metal Stamping Dies , Mass Production Injection Molding , Metal Stamping Parts Processing , Mold Base

- Capital (Million US $): US$1 Million - US$2.5 Million

- Year Established: 2010

- Total Annual Sales Volume (Million US $): US$5 Million - US$10 Million

- Export Percentage: 51% - 60%

- No. of Production Lines: 50

- No. of R&D Staff: 11 -20 People

- No. of QC Staff: 5 -10 People

- OEM Services Provided: YES

- Factory Size (Sq.meters): 5,000-10,000 square meters

- Factory Location: No.298 Jianlin Road,Zhangpu Town,Kunshan City,215300,Suzhou,Jiangsu Province, China.

- Contact Person: Mr. Chan

- Tel: 86-512-57999246

Premium Related Products

Other Products

Hot Products

Slth Stamping Parts with Different Surface TreatmentSlth CNC Bendig Wire Forming Spring /Professional ManufacturerYangzhou Slth Serpentine Spring / Snake Spring with High Quality and Best PriceCustomized Auto Parts Elastic Element Oil Seal SpringCustomized Pipe Pressure Spring with High QualityVarious Shape Custom Carbon Steel Scroll SpringHigh Quality Customized Steel Wire Form Springs ProductsCustomized Precision CNC Machining PartsCustomized Various Torsion SpringsOEM ODM Customized High Quality Stainless Steel Stamping PartsHigh Quality OEM Metal Stamping PartsHeavy Black Finish Compression Spring Coil SpringChina Manufacturer Custom Steel Helical Compression Bending Banana SpringsBattery Electric Contact Plate Compression SpringsOpen or Close Snap Spring with High Quality Competitive PricesCustomized Experienced Design Extension Springs for Fitness Equipment