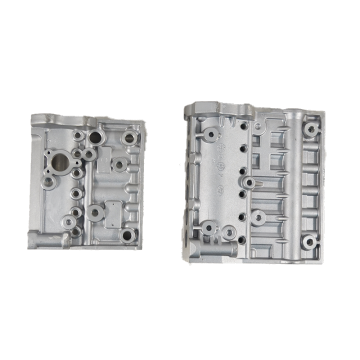

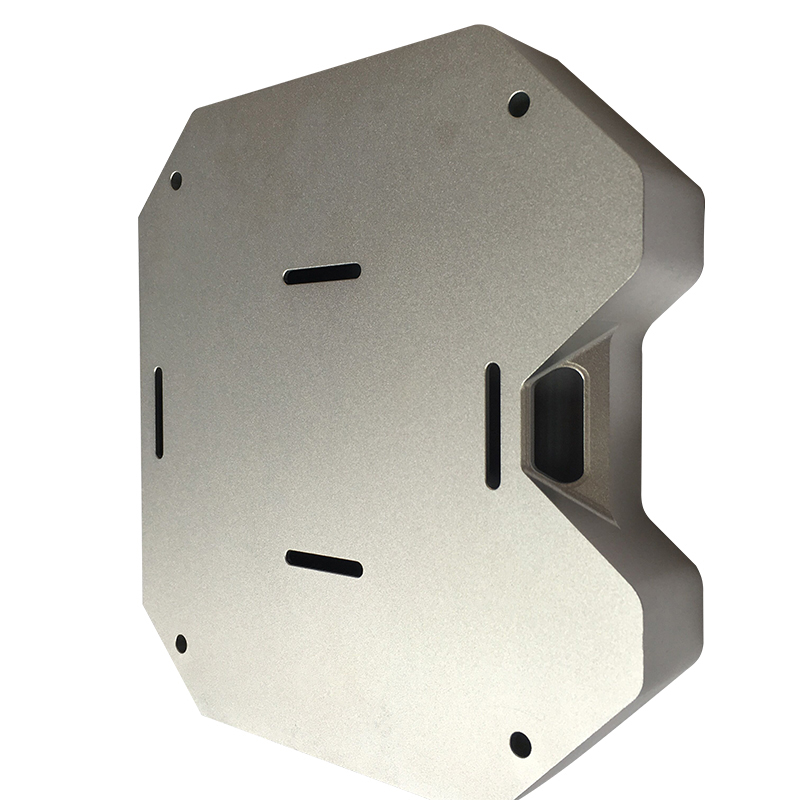

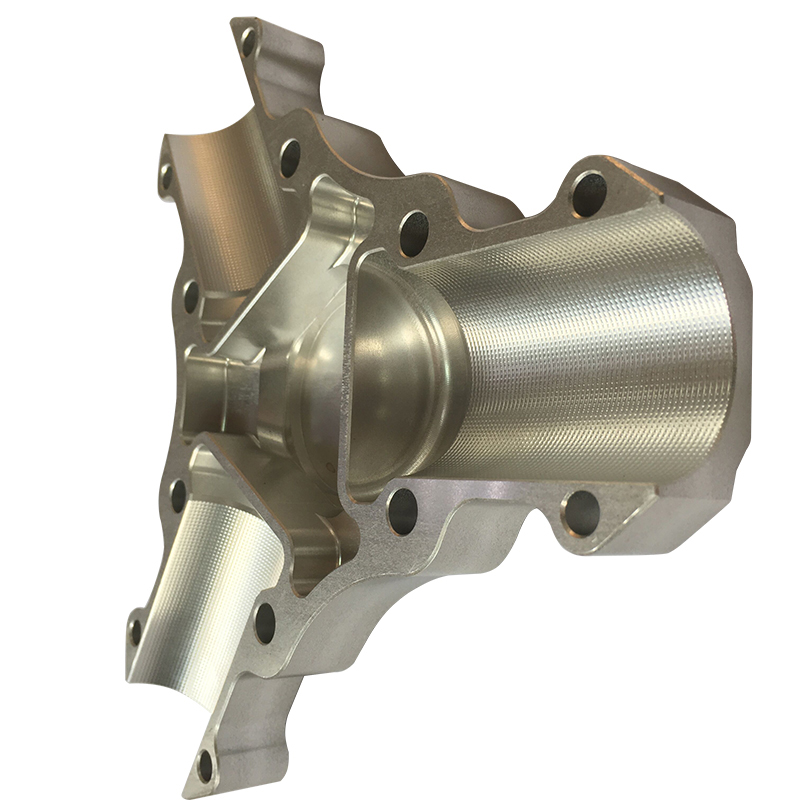

cnc machining cast aluminum engine assembly parts

Product Description

What Is CNC Machining?

Computer Numerical Control (CNC) machining is a manufacturing system that uses a combination of computer inputs and computer controlled machining tools.

The parts needed are designed using Computer Aided Design (CAD) software. Those CAD designs are then translated into a series of instructions that can be understood by the computer controlled machining tools.

These instructions are often referred to as G-code. Once the G-code is running, the CNC process requires little or no oversight. It is also capable of producing prototype parts to very exact specifications.

CNC machining is a subtractive manufacturing process. This means that computer controlled machining tools remove material from a block of material, known as the workpiece.

CNC machines themselves vary in their levels of complexity. The more axes a machine has, the more complicated a geometry it can cut into the workpiece.

The Rapid Prototyping Process with CNC Machining

Rapid prototyping is first conceptualised into the 1970s in response to advances in manufacturing technology. It represents a solution to the bottlenecking of the design process that traditional prototyping represented.

The rapid prototyping process has a number of advantages, such as:

The ability to explore concepts in a low-cost low-risk environment. Because of the cost and time effective nature of CNC prototyping and 3D printing, designers are able to explore new designs and new materials with greater freedom.

Regardless of how good your CAD software is, nothing helps with the communication of ideas more effectively than holding a physical object. This is especially true when using proof of concept models to attract investors or drive sales.

The speed at which new prototypes can be produced by rapid prototyping services means that designers can quickly and effectively incorporate testing results and feedback into new iterations on the base design.

A combination of the factors listed above means the employing rapid prototyping alongside new additive and subtractive manufacturing options, allows design departments to more thoroughly test their prototypes and minimize potential design flaws that could have cost and functionality implications later on.

Why Choose Bergek

professional custom CNC Machining Parts Manufacturer in China

* Guangdong Aluminum Application Precision Technology Co, Ltd was established in 2012 and has over 10 years experience of in researching. developing and manufacturing CNC Machining Parts

* We have the recognition of famous brand customers all over the world

* Our company has more than 200 professional employees and over 10000 sqm modern factory area

* Our products own many patents and quality system certifications ISO 9001

* Our products own many patents and quality system certifications ISO 9001 is over 250,000 tons, exported to over 120 countries.

Product Categories : CNC Turning > Turning Aluminum Parts